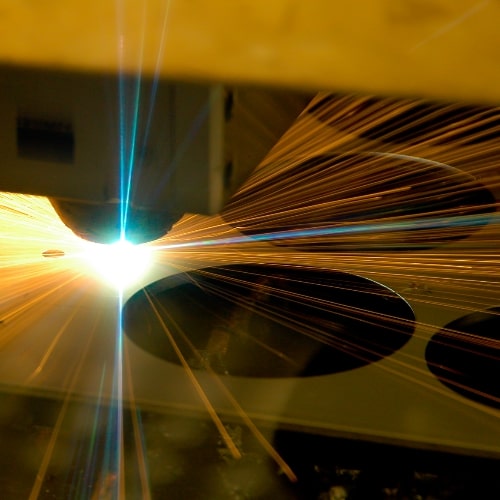

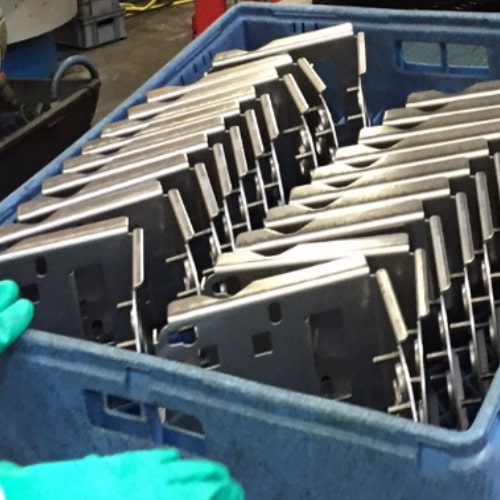

Processing of sheet metal

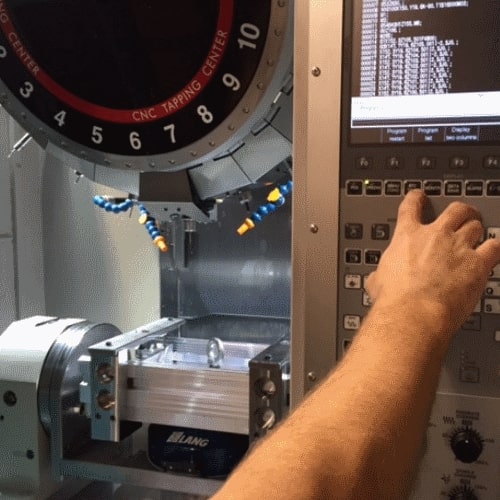

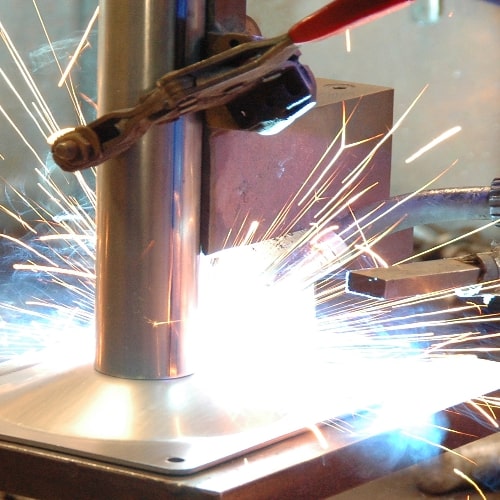

Stantræk is among the leading partners in metal processing. We have achieved this by making ongoing investments in high-tech equipment.

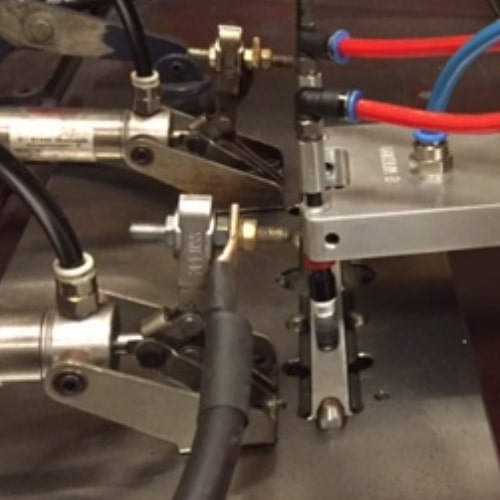

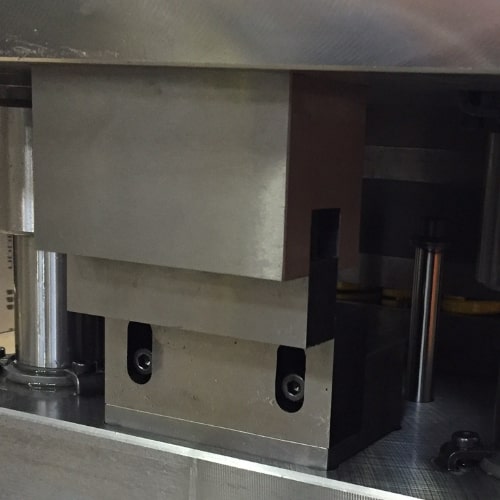

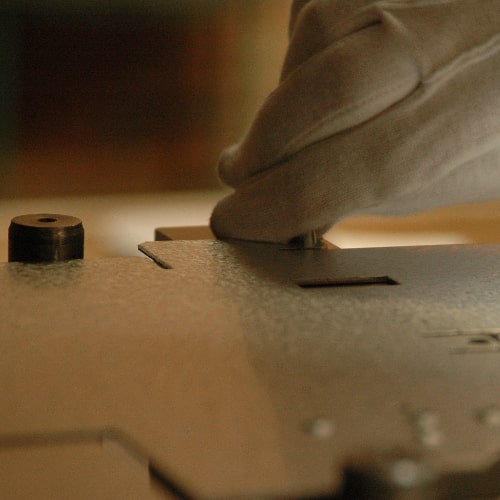

Our machinery ranges widely – from fully automatic cnc punching machines, fiber laser cutters, robotic cells for bending, PEM serters and manual production machines. The wide range of modern production equipment allows us to turn customer designs into tangible parts at short notice. And we like to be challenged!

Our team of experienced specialists ensures that our customers’ wishes and requirements are translated into timely delivery of high-quality metal components.

Danish Company

Danish Company